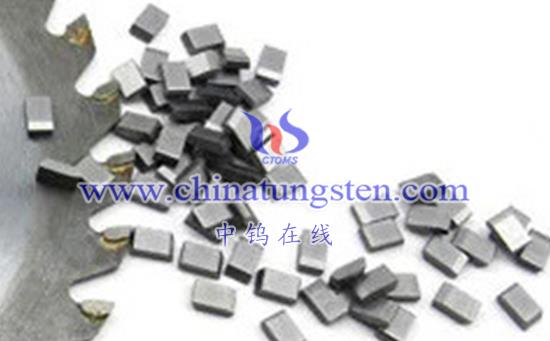

The main reasons why high-hardness tungsten steel saw blades can ensure cutting accuracy are as follows:

- Material stability: Tungsten steel material has high hardness and good stability, which can effectively ensure that no deformation or breakage occurs during the cutting process, reducing errors and burrs.

- Precise manufacturing process: The manufacturing process of high-hardness tungsten steel saw blades is very precise, including grinding, polishing and other processes to ensure the flatness and accuracy of the saw blades.

- Geometric accuracy: During the design and manufacturing process of high-hardness tungsten steel saw blades, their geometric shape and size are precisely controlled to ensure cutting accuracy and consistency.

- Use environment control: During use, you can reduce the impact of the external environment on cutting accuracy by controlling cutting speed, pressure, coolant and other parameters.

- Correct operation method: Correct operation method is also one of the key factors to ensure the cutting accuracy of high-hardness tungsten steel saw blades. For example, keep the saw blade clean and sharp, use correct sawing parameters, etc.

In short, high-hardness tungsten steel saw blades can ensure cutting accuracy and consistency through material stability, precise manufacturing processes, geometric accuracy control, use environment control, and correct operating methods.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595