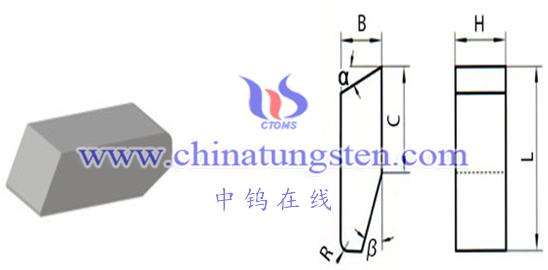

YG6 alloy sawtooth grains have the following characteristics:

- High hardness: YG6 alloy serrated grains are made of tungsten steel material, which has high hardness and good wear resistance, and can withstand high-intensity cutting loads.

- High wear resistance: YG6 alloy sawtooth grains have high wear resistance, which can effectively reduce the wear and deformation of the saw blade and improve cutting accuracy and efficiency.

- Strong impact resistance: YG6 alloy serrated grains have good impact resistance and can withstand large impact forces during the cutting process, reducing blade breakage.

- High cutting efficiency: The sharp edges and high hardness of YG6 alloy serrated grains can increase cutting speed and reduce heat generation, thus improving cutting efficiency.

- High cutting accuracy: Due to the high hardness and high wear resistance of YG6 alloy sawtooth grains, it can effectively reduce the wear and deformation of the saw blade, thus improving the cutting accuracy.

- Long life: Due to the high hardness and high wear resistance of YG6 alloy sawtooth grains, it can effectively reduce the wear and deformation of the saw blade, thereby extending the service life of the saw blade.

- Wide range of application: YG6 alloy sawtooth grains are suitable for various materials and cutting occasions, including cutting of wood, metal, plastic and other materials.

- Strong customizability: Different specifications of YG6 alloy sawtooth grains can be selected according to different needs and cutting occasions to meet the needs of different customers.

In short, YG6 alloy serrated grain has the advantages of high hardness, high wear resistance, strong impact resistance, high cutting efficiency, and high precision. It is an excellent cutting tool material.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595