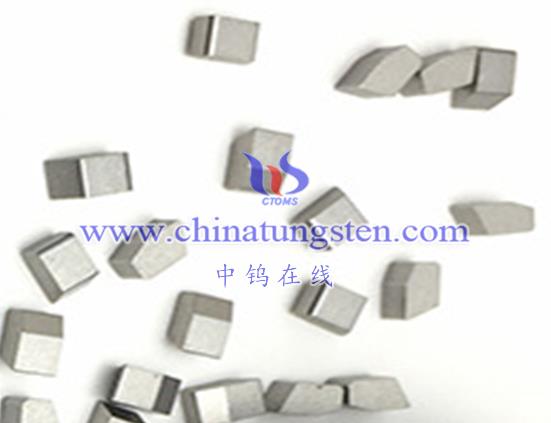

Hard Alloy High-Low Teeth is a specially designed cutting tool commonly used for cutting wood and similar materials. The tooth profile of this cutting tool features alternating high and low teeth to provide greater cutting efficiency and smoother cut quality. The following are the main features of carbide high and low teeth:

- Alternate arrangement of high and low teeth: The tooth shape of this cutting tool is composed of high teeth and low teeth alternately arranged. High teeth are usually slightly taller than low teeth, allowing for faster material removal when cutting.

- Suitable for wood cutting: Carbide high and low teeth are usually used for cutting wood, including softwood and hardwood. Its design helps speed up cutting while providing a smooth cutting edge.

- Reduce vibration and noise: Due to the alternating arrangement of high and low teeth, less vibration and noise will be generated when cutting, which helps to improve the comfort and safety of operation.

- Efficient Cutting: Since tall teeth can remove material faster, carbide high and low teeth often provide efficient cutting, especially in high-volume wood cutting tasks.

Carbide high and low teeth are common cutting tools in the field of woodworking and are used for tasks such as making furniture, building structures, and floor installations. Its special design is designed to provide efficient, smooth cuts while reducing vibration and noise during operation.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595