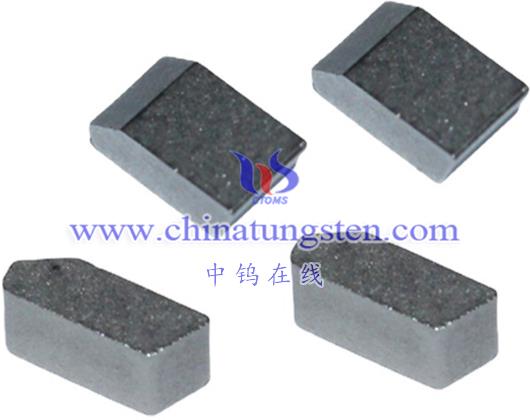

Tungsten carbide saw blade is a serrated cutting tool made of tungsten carbide, which has the characteristics of high hardness, high wear resistance and heat resistance. It is mainly used for cutting various hard materials, such as carbide, ceramics, quartz, glass, etc., and is widely used in industrial manufacturing, construction, maintenance and other fields.

The manufacturing process of tungsten carbide saw blades includes batching, molding, sintering, grinding and coating. Its high hardness can ensure that it will not become dull during high-speed cutting and continue to maintain a sharp cutting edge. At the same time, its high wear resistance also allows the saw blade to maintain its cutting performance for a long time and improve production efficiency.

The characteristics of tungsten carbide saw blades include high hardness, high wear resistance, heat resistance, high cutting efficiency, repeatable grinding and use, suitability for various materials, long service life, and customization. However, it also has some disadvantages, such as higher equipment requirements, the need for professional operators, and high maintenance and replacement costs.

When using tungsten carbide saw blades, you need to pay attention to using special coolant to keep its temperature stable, and choose the appropriate cutting speed and cutting depth. At the same time, the saw blade needs to be inspected and maintained regularly to ensure its normal operation and extend its service life.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595