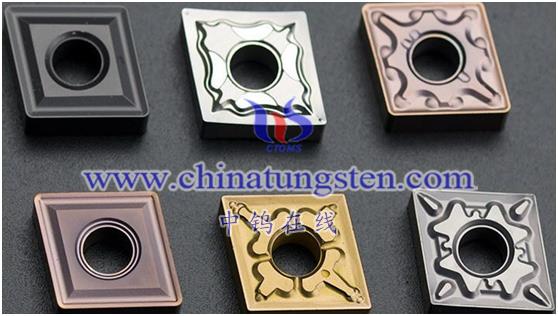

Carbide coated inserts have the following features:

High hardness: The carbide matrix itself has high hardness, and coating materials such as titanium nitride and titanium carbide also have high hardness. Therefore, the hardness of the coated blade is relatively high and can maintain the edge during the cutting process. Mouth wear resistance and long life.

Excellent wear resistance: The coating of the coated blade has good wear resistance, which can reduce edge wear and extend the service life of the tool under high-speed cutting and heavy-load cutting conditions.

High thermal stability: The coating material of the coated blade has high thermal stability and thermal conductivity, which can effectively disperse and remove the heat generated during the cutting process, reducing the risk of thermal deformation and thermal cracks of the tool.

Low friction coefficient: The coating of the coated insert has a low friction coefficient, which can reduce friction and heat accumulation between the tool and the workpiece, reduce cutting force and cutting temperature, and improve cutting efficiency.

Good cutting quality: Coated inserts can provide a smoother cutting surface, reduce burrs and roughness on the cutting surface, and improve the surface quality of the workpiece.

Multifunctional application: The coating of the coated insert can be adjusted and optimized according to different processing requirements, and can be used in different application fields such as high-speed cutting, dry cutting, precision machining, and heavy cutting.

Environmentally friendly: The coated blade has a long service life, which reduces the frequency of tool replacement, thereby reducing the consumption of waste materials and resources, and has certain saving benefits for the environment.

In general, carbide-coated inserts have the advantages of high hardness, good wear resistance, high thermal stability, and good cutting quality. They are widely used in the field of metal cutting processing, improving processing efficiency and workpiece quality.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595