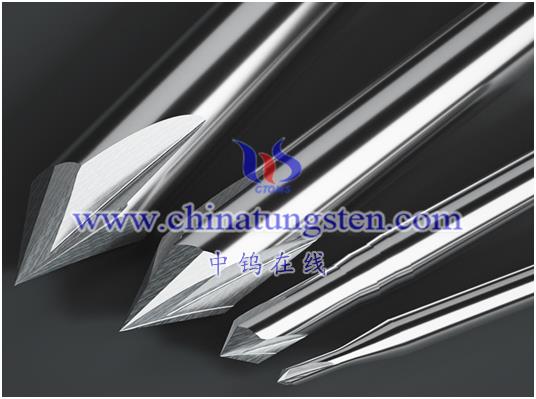

A carbide straight groove cutter is a cutting tool used to cut straight grooves in workpieces. It is usually made of cemented carbide material, which is a composite material composed of tungsten carbide (WC) and cobalt (Co). It has high hardness, wear resistance and high temperature resistance, and is suitable for high-speed cutting. and durable tools. The tool shape and size of carbide straight groove cutters are determined according to the required groove parameters, such as groove width, depth, cutting angle, etc. It usually has multiple cutting edges and is used to cut straight channels in the workpiece. When using carbide straight groove cutters for linear groove machining, a tool holder and tool holder are usually required to hold and drive the cutting tool. The straight groove cutter can cut the workpiece through rotation and feed motion to form the required straight groove shape. Carbide straight groove cutters are widely used in the field of groove processing in the manufacturing industry, such as machining, mold manufacturing, metal processing, etc. It can efficiently and accurately cut straight channels to meet the processing needs of different workpieces.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595