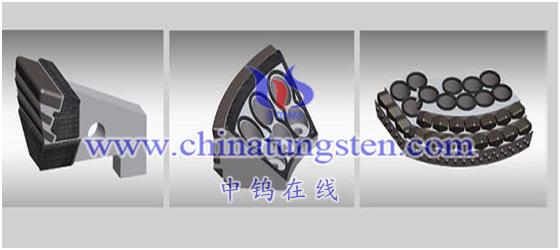

Carbide shield cutting tools have the following advantages and characteristics:

High hardness and high wear resistance: The carbide shield cutter has high hardness and wear resistance, which can quickly cut and excavate soil and rocks during the excavation process, improve the excavation efficiency, and reduce the wear of the shield machine.

Strong adaptability: Carbide shield cutters can cope with different geological conditions, such as soft soil, sand, rocks, etc. Under different geological conditions, its cutting and excavation capabilities are fully demonstrated, helping the shield machine to advance smoothly.

Good support and stability: The carbide shield knife can provide better support and stability, help the shield machine maintain a straight trajectory, reduce deflection and vibration, thereby reducing the risk of damage to the shield machine.

Easy to replace and repair: The replacement and repair of the carbide shield knife is relatively easy because its structure is relatively simple. When the cutting tools are worn or damaged, they can be replaced in time to ensure the normal operation of the shield machine.

High reliability: Due to the stable structure and reliable quality of the carbide shield knife, it has high reliability during use and reduces the probability of shield machine failure.

In summary, cemented carbide shield cutting tools have the advantages of high hardness and high wear resistance, strong adaptability, good support and stability, easy replacement and maintenance, and high reliability. In shield tunneling The machine plays an important role in the excavation process.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595