The following are several specific application cases of cemented carbide in medical devices:

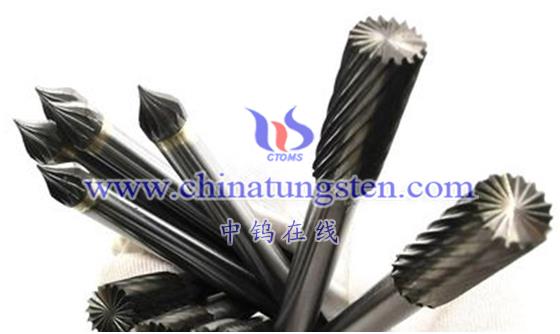

- Surgical tools: Carbide is widely used in surgical blades and scissors. These tools need to have high hardness and high wear resistance to effectively cut and polish tissue during surgery. In addition, carbide is also used to make surgical screwdrivers and other instruments to meet special needs in surgery.

- Medical materials: Carbide is also widely used in medical materials. For example, in orthopedic internal fixation materials, titanium metal plates and stainless steel plates are used to manufacture internal fixations. These materials are required not only to have high strength and corrosion resistance, but also to have good compatibility with human tissue so that they can be implanted into the body for a long time.

- Medical device parts: Carbide is also used to manufacture some key parts of medical devices, such as needles, catheters, dental appliances, etc. These parts need to have good biocompatibility and corrosion resistance, and also need to meet some special requirements in medical operations.

- Carbide coating: Carbide coating is also used in the surface coating of medical devices to improve its corrosion resistance and biocompatibility. This coating material has extremely high hardness, wear resistance and corrosion resistance, which can effectively improve the performance and service life of medical devices.

In short, cemented carbide is widely used in medical devices. These application cases show the important position and role of cemented carbide in medical device manufacturing.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595