Carbide has good thermal stability. In high-temperature environments, the carbide particles in cemented carbide are not easy to melt or decompose, and their crystal structure is relatively stable. Therefore, in high-temperature environments, the properties of cemented carbide change very little and have good dimensional stability and forming stability.

The thermal stability of cemented carbide is mainly affected by its material composition and crystal structure. For example, the carbides in tungsten carbide cemented carbide have high melting point (2400~3140℃), high hardness (1800~3200HV), high elastic modulus (291~710GPa), good chemical stability and good thermal stability, making it Shows better performance in high temperature environments.

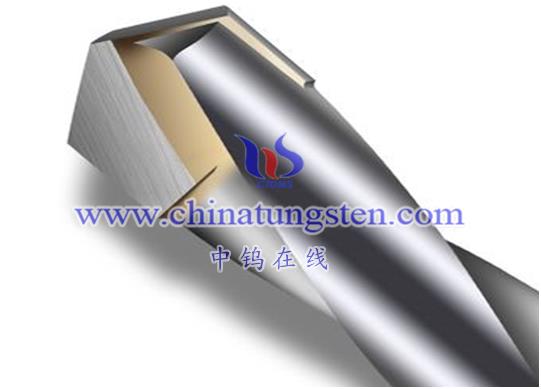

In addition, the flexural strength of cemented carbide is also very high, up to 3500~4000MPa, which is even higher than the flexural strength of high-speed steel. This high strength allows cemented carbide to make high-strength tools such as small-diameter drill bits, end mills, thin large-diameter saw blade milling cutters, and various taps.

In short, because cemented carbide has good thermal stability and high strength, it can maintain good performance and shape stability in high temperature environments, so it is widely used in manufacturing high-performance cutting tools, drill bits, saw blades, etc. Wear resistant tools.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595