There are some differences in the uses of high-speed steel and carbide.

High-speed steel is a tool steel with high hardness, high wear resistance and high heat resistance, so it is mainly used to manufacture high-speed cutting tools, cutting tools and measuring tools. In terms of high-speed cutting tools, high-speed steel can be used to manufacture high-speed wire saws, high-speed steel circular saw blades, high-speed steel turning tools, etc. In terms of cutting tools, high-speed steel can be used to manufacture cutting tools, drill bits, taps, milling cutters, etc. of various shapes. In terms of measuring tools, high-speed steel can be used to manufacture various measuring tools, such as gauges, block gauges, plug gauges, etc.

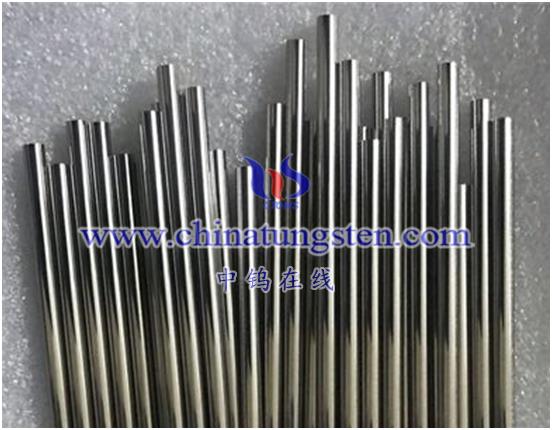

Carbide has high hardness and strength, so it is mainly used to make high-performance wear-resistant tools, such as carbide cutting tools. In terms of cutting tools, carbide can be used to manufacture carbide cutting tools of various shapes, such as carbide circular saw blades, carbide turning tools, etc. In addition, carbide can also be used to manufacture high-performance wear-resistant parts, such as carbide sealing rings, carbide pump parts, etc.

In general, high-speed steel is mainly used to make high-speed cutting tools, cutting tools and measuring tools, while cemented carbide is mainly used to make high-performance wear-resistant tools, such as carbide cutting tools.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595