The sintering process of cemented carbide is a manufacturing process in which powdered cemented carbide materials are sintered into a green body under high temperature and high pressure conditions. The following are the main steps of the process:

- Molding agent removal and pre-burning stage: In this stage, the molding agent gradually decomposes or vaporizes and discharges the sintered body. The molding agent will more or less carbonize the sintered body. The amount of carburization will change with the type and quantity of molding agent and the sintering process. At the same time, the surface oxides of the powder are reduced, and at the sintering temperature, hydrogen can reduce the oxides of cobalt and tungsten.

- Recovery and recrystallization of bonded metal powder: The contact stress between powder particles is gradually eliminated, bonded metal powder begins to recover and recrystallize, surface diffusion begins to occur, and the strength of the compact is improved.

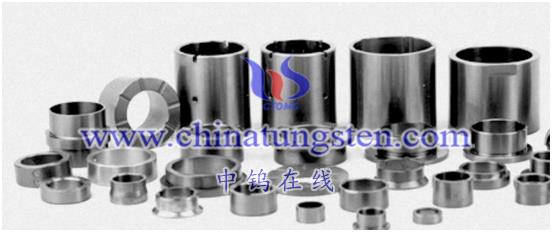

The principle of the sintering process is to utilize the plastic deformation of powder particles and the diffusion between particles under high temperature and high pressure to combine adjacent particles with each other to form a dense body. Sintered cemented carbide has the characteristics of high hardness and high wear resistance, and is widely used in the manufacture of high-performance cutting tools, molds and wear-resistant parts.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595