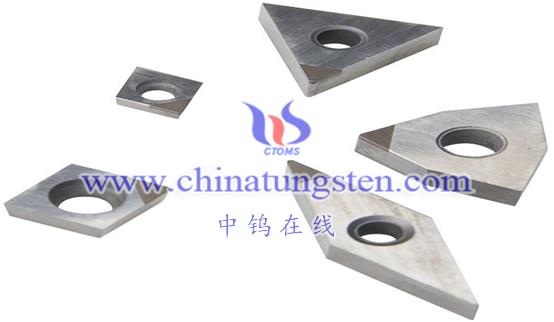

CBN blades refer to blades made of cubic boron nitride (CBN). CBN is an artificial super-hard material, its hardness is second only to diamond. CBN inserts have excellent cutting performance and wear resistance in cutting processing, and are especially suitable for processing difficult-to-machine materials such as hard materials and high-temperature alloys. CBN blades have the following features:

High hardness: The hardness of CBN is close to natural diamond and several times that of cemented carbide, so it can effectively cut materials with higher hardness.

Wear resistance: CBN blades have excellent wear resistance, which can keep the cutting edge of the tool sharp for a long time and extend the tool life.

High temperature resistance: CBN inserts can maintain stable cutting performance under high temperature conditions and are suitable for high temperature processing and high speed cutting.

Resistance to chemical corrosion: CBN blades have high resistance to acid, alkali and chemical corrosion, and can work in harsh environments.

High cutting efficiency: Because CBN inserts have high cutting speed and long tool life, they can improve cutting efficiency and production efficiency.

CBN inserts are widely used in the cutting of high-hardness materials, such as carbide, thermal spray coatings, high-speed cutting steel, etc., as well as roughing and finishing of high-temperature alloys. They are widely used in aerospace, automobile manufacturing, mold manufacturing, oil drilling and other fields.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595