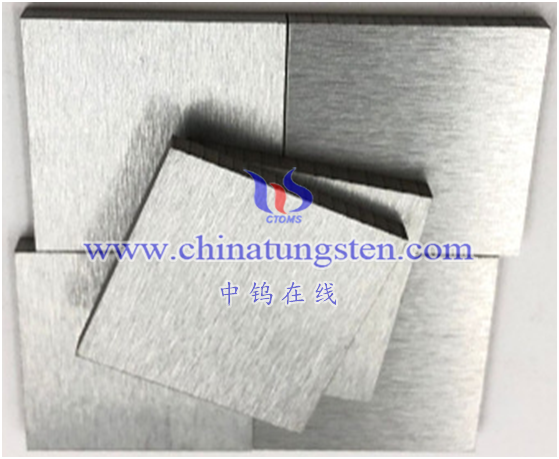

The production process of high-density tungsten alloy mass block mainly includes the following steps:

- Melting and mixing: Put tungsten, nickel, iron and other metal elements into a high-temperature smelting furnace to melt, and stir and mix thoroughly.

- Pressing: Pour the mixed molten metal into the mold and press it into shape.

- Cooling and demoulding: Cool the pressed mass block and remove it from the mold.

- Grinding and processing: Grind and process the demoulded mass block to remove surface burrs, oxide layers and other defects to meet the specified quality and dimensional accuracy requirements.

- Testing and calibration: Strictly test and calibrate the processed mass blocks to ensure that they comply with international standards and specified error ranges.

During the entire production process, the quality and process parameters of each link need to be strictly controlled to ensure that the quality and performance of the final product meet the requirements. At the same time, necessary safety measures are also required, such as wearing protective clothing and using safety equipment, to ensure safety during the production process.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595