There are some obvious differences between tungsten-molybdenum-nickel-iron alloy and molybdenum-vanadium-iron alloy in composition, performance and application.

First of all, from the composition point of view, tungsten-molybdenum-nickel-iron alloy is mainly composed of elements such as tungsten, molybdenum, nickel and iron, while molybdenum-vanadium iron alloy is composed of elements such as molybdenum, vanadium and iron. This compositional difference results in differences in properties between the two alloys.

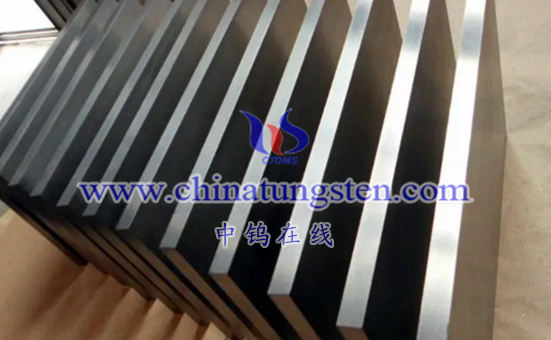

Secondly, tungsten-molybdenum-nickel-iron alloy is known for its high strength, high hardness, good thermal stability and corrosion resistance. It also has a low expansion coefficient, high thermal conductivity and good red hardness, which makes it widely used in die-casting molds, hot forging valves, hot riveting bearing materials and other fields. In addition, the alloy has good electrical and thermal conductivity and is therefore also used in the electronics and lighting industries.

Molybdenum-vanadium iron alloy is characterized by its high strength, high hardness, good wear resistance and corrosion resistance. It is usually used to manufacture wear-resistant and corrosion-resistant parts and tools, such as cutting tools, abrasive tools, wear-resistant plates, etc. In addition, molybdenum-vanadium iron alloy also has good high-temperature properties and can maintain good stability in high-temperature environments. Therefore, it is also used in high-temperature fields, such as aerospace, energy, etc.

Finally, in terms of application, although tungsten-molybdenum-nickel-iron alloy and molybdenum-vanadium-iron alloy overlap in some fields, it is very important to choose the appropriate alloy material according to the specific use needs and performance requirements. For example, in applications that require a combination of high strength, high thermal stability, and corrosion resistance, tungsten-molybdenum-nickel-iron alloys may be more suitable, while in applications that require high wear resistance and high-temperature performance, molybdenum-vanadium-iron alloys may be more advantageous. .

To sum up, there are obvious differences between tungsten-molybdenum-nickel-iron alloy and molybdenum-vanadium-iron alloy in terms of composition, performance and application. The selection of suitable alloy materials should be determined based on specific usage scenarios and needs.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595