Tungsten-molybdenum-nickel-iron alloy is a metal alloy mainly composed of tungsten, molybdenum, nickel and iron. This alloy is produced by powder metallurgy and has some unique physical and chemical properties, such as low density, high strength, high hardness, good electrical and thermal conductivity, and excellent corrosion resistance and oxidation resistance.

Tungsten in tungsten-molybdenum-nickel-iron alloy is a high melting point metal with high strength, high hardness and corrosion resistance, and is the main reinforcing element of the alloy. The addition of molybdenum can further improve the corrosion resistance, high temperature performance and hardness of the alloy. Nickel is a metal with good toughness and corrosion resistance, which can improve the ductility and wear resistance of the alloy. Iron, as the base metal of the alloy, provides the alloy with good processability and mechanical properties.

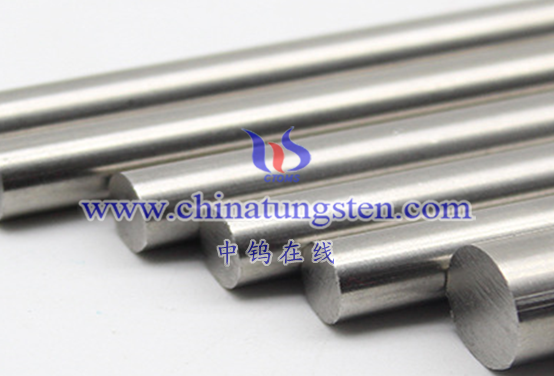

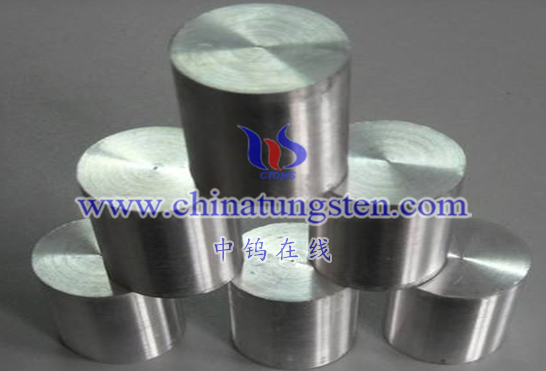

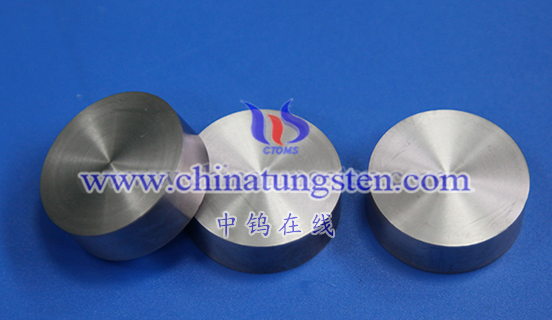

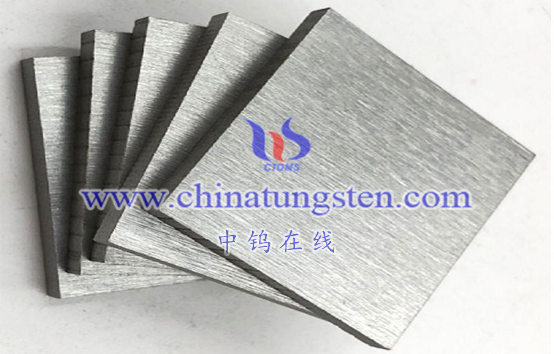

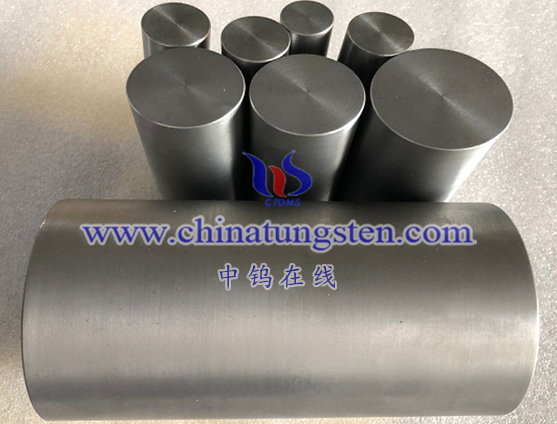

Due to these excellent properties, tungsten-molybdenum-nickel-iron alloys are widely used in many fields, such as die-casting molds, anvil blocks for hot forging valves, wear-resistant and corrosion-resistant parts and tools, high-density alloys such as radiation protection and vibration absorption), etc. In addition, according to customer needs, non-standard tungsten-based high specific gravity alloys can also be customized.

In general, tungsten-molybdenum-nickel-iron alloy is an important metal alloy with good mechanical properties, high temperature stability and corrosion resistance. It is widely used in many fields, including aerospace, energy, chemical industry, automobile manufacturing, etc.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595