90tungsten-molybdenum-nickel-iron alloy is a special metal alloy that has been widely used in many fields due to its excellent physical and chemical properties. The following is a detailed explanation of the main uses of 90 tungsten molybdenum nickel iron alloy:

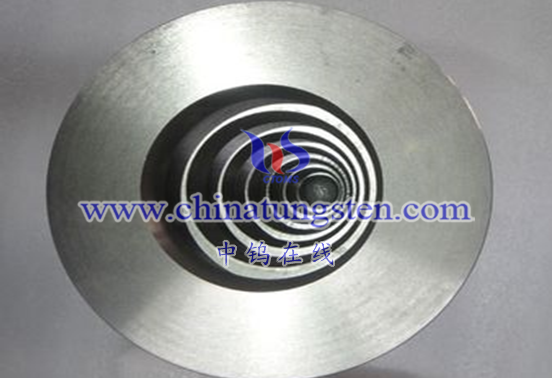

Die casting mold field

Because 90 tungsten-molybdenum-nickel-iron alloy has high thermal conductivity, good red hardness and low expansion coefficient, it has become an ideal material for manufacturing die-casting molds. Die-casting molds need to work under high temperature and high pressure conditions, and this alloy can maintain the stability of its shape and performance, ensuring the accuracy and durability of the mold.

Hot riveting bearing materials

Hot riveting bearing material (90WMoNiFe/93WNiFe), due to its good comprehensive high temperature performance, this material can be used as hot riveting bearing material;

Hot stamped valve material

90 tungsten-molybdenum-nickel-iron alloy has both thermal conductivity and high-temperature performance, and maintains good red hardness at 1100°C. As an electric anvil block for valve stamping, it can significantly increase the service life of the anvil block. 90 tungsten-molybdenum-nickel-iron alloy is widely used as a material for hot forging valve anvils due to its excellent thermal conductivity and high temperature performance. During the hot forging process, the anvil block needs to withstand the impact of high temperature and pressure, and the alloy can maintain its hardness and strength, significantly increasing the service life of the anvil block.

Aviation and spacecraft components

Due to its high strength and good high temperature resistance, 90 tungsten-molybdenum-nickel-iron alloy is often used to manufacture key components in aviation and spacecraft, such as gyroscope rotors, guide devices, and shock absorbers. These parts need to be able to withstand extreme temperature and pressure conditions, and this alloy meets these requirements.

Machinery manufacturing field

In the field of machinery manufacturing, 90 tungsten-molybdenum-nickel-iron alloy is often used to manufacture die-casting molds, tool holders, boring bars and other components. These parts need to have high hardness and wear resistance to cope with the friction and wear during machining.

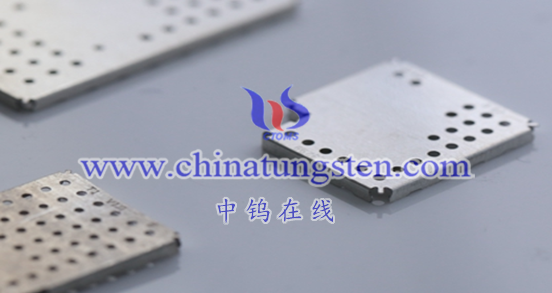

Conventional weapons and electrical products

In conventional weapons manufacturing, the alloy can be used as core material for armor-piercing projectiles, while in electrical products, it can be used as components such as rivet heads and switch contacts. These applications take full advantage of the high hardness and excellent electrical conductivity of 90tungsten-molybdenum-nickel-iron alloy.

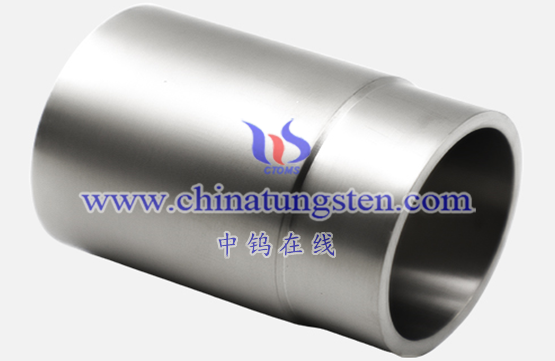

Radiation shielding parts

Because its ability to absorb radiation is stronger than lead, 90 tungsten-molybdenum-nickel-iron alloy is also used to manufacture various radiation-proof shielding components, providing important safety protection for the nuclear industry and medical fields.

Although 90 tungsten molybdenum nickel iron alloy has many excellent properties and application fields, its specific use needs to be determined based on specific working conditions and requirements. At the same time, with the advancement of science and technology and the continuous improvement of processes, the application fields of 90 tungsten-molybdenum-nickel-iron alloy will continue to expand and deepen.

In summary, 90 tungsten-molybdenum-nickel-iron alloy plays an important role in many fields with its unique physical and chemical properties, providing strong support for the development of modern industry.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595