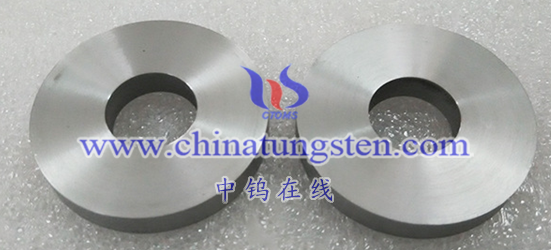

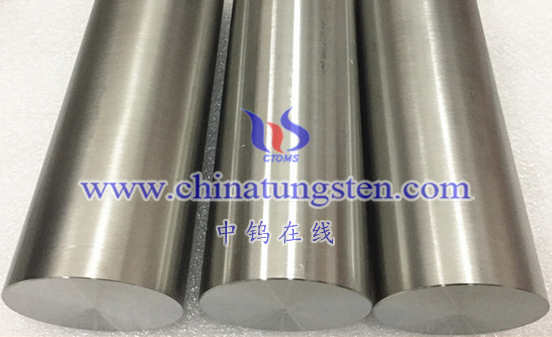

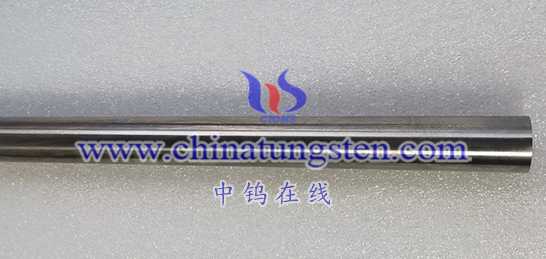

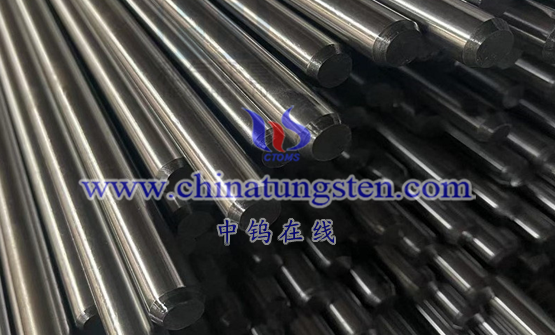

Tungsten-molybdenum-nickel-iron alloy is a special metal material that is widely used in many fields due to its excellent properties such as high strength, high hardness, high wear resistance and high thermal stability.

Composition and properties of tungsten-molybdenum-nickel-iron alloy

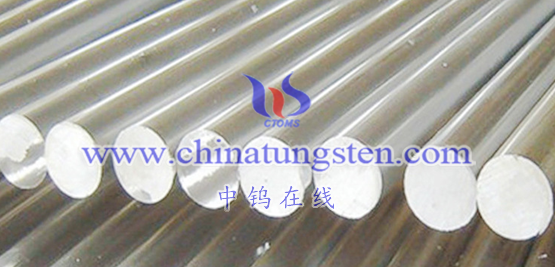

Tungsten-molybdenum-nickel-iron alloy is mainly composed of four elements: tungsten (W), molybdenum (Mo), nickel (Ni) and iron (Fe). The content of each element can be adjusted according to specific needs. The hardness, strength, wear resistance and thermal stability of this alloy mainly depend on the content and proportion of each element.

Tungsten (W)

Tungsten is a metal element with high melting point and high hardness, which can significantly improve the strength and hardness of alloys.

Molybdenum (Mo)

Molybdenum also has the characteristics of high melting point and high hardness. Used together with tungsten, it can enhance the wear resistance and thermal stability of the alloy.

Nickel (Ni)

Nickel is a metallic element with good toughness and ductility, which can improve the plasticity and processing properties of the alloy.

Iron (Fe)

Iron is the main matrix element of the alloy and has good thermal conductivity and electromagnetic properties.

Preparation process of tungsten-molybdenum-nickel-iron alloy

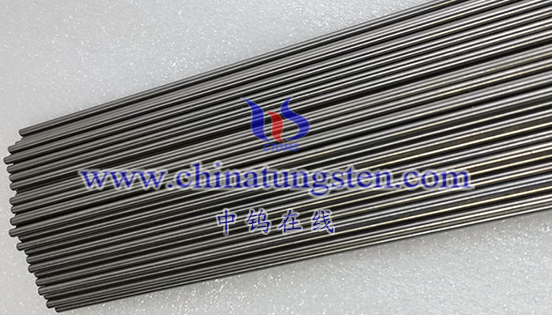

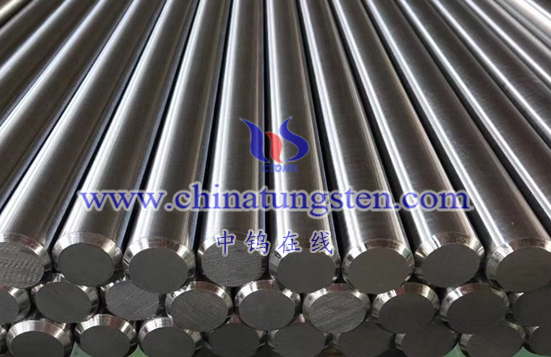

Tungsten-molybdenum-nickel-iron alloy is usually prepared by powder metallurgy, smelting or vacuum smelting. Among them, powder metallurgy is widely used because of its ability to precisely control alloy composition and microstructure. During the preparation process, raw materials need to be carefully processed and smelting conditions strictly controlled to ensure stable performance of the alloy.

Performance characteristics of tungsten molybdenum nickel iron alloy

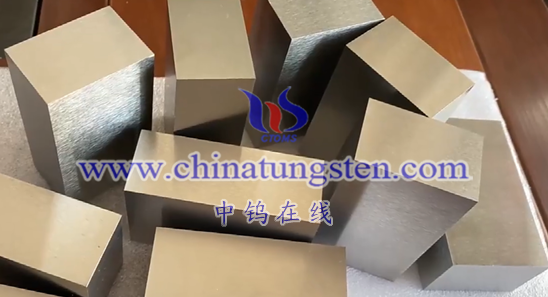

High strength and hardness

The high hardness properties of tungsten and molybdenum make tungsten-molybdenum-nickel-iron alloy extremely strong and hard, making it suitable for applications that can withstand high loads and wear.

High wear resistance

The tungsten and molybdenum elements in the alloy can effectively improve the wear resistance of the material, allowing it to maintain good performance in harsh working environments.

High thermal stability

The high melting points of tungsten and molybdenum make tungsten-molybdenum-nickel-iron alloy have excellent high-temperature properties and can maintain good strength and hardness at high temperatures.

Good electromagnetic properties

The presence of iron element makes the alloy have good electrical conductivity and magnetic properties, making it suitable for applications in the electromagnetic field.

Application fields of tungsten-molybdenum-nickel-iron alloy

Because tungsten-molybdenum-nickel-iron alloy has excellent performance characteristics, it is widely used in many fields. For example:

Aerospace field

Used to manufacture high-temperature components, wear-resistant parts, engine blades, etc.

Energy field

Used to manufacture wear-resistant parts and high-temperature components for nuclear energy equipment, as well as reflectors for solar energy equipment.

Machinery manufacturing

Used to manufacture wear-resistant and high-strength components such as cutting tools, molds, and bearings.

Electronic information field

Used to manufacture high-temperature electronic components, magnetic materials, etc.

Development trend of tungsten-molybdenum-nickel-iron alloy

With the advancement of science and technology and the development of industrial production, the performance requirements for tungsten-molybdenum-nickel-iron alloys are also constantly increasing. In the future, the development of tungsten-molybdenum-nickel-iron alloy will show the following trends:

Ingredient optimization

By adjusting the alloy composition, the properties of the alloy are further optimized to meet the needs of different fields.

Preparation process innovation

New preparation processes and technologies are adopted to improve the purity and uniformity of the alloy and further improve its performance.

Composite Materials Research

Composite tungsten-molybdenum-nickel-iron alloy with other high-performance materials to create new composite materials with higher performance.

Green

In the alloy preparation and application process, we pay attention to environmental protection and sustainable development, and reduce energy consumption and environmental pollution.

As an important high-performance metal material, tungsten-molybdenum-nickel-iron alloy plays an important role in modern industry. Through continuous research and innovation, the performance of tungsten-molybdenum-nickel-iron alloy will be further improved, and its application fields will continue to expand, making greater contributions to promoting scientific and technological progress and industrial development.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595