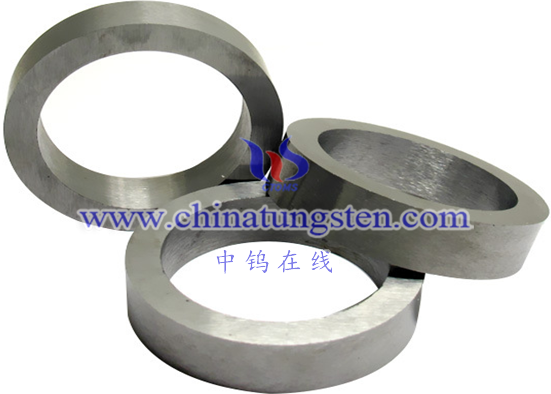

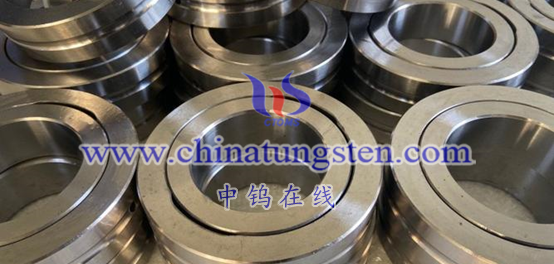

Hot riveting bearing materials usually refer to materials used in the bearing hot riveting process. This process involves the application of hot riveting technology on bearings to achieve specific connection or fixing purposes. When selecting hot riveting bearing materials, many factors need to be considered, including the material’s strength, wear resistance, heat resistance, thermal expansion coefficient and compatibility with other materials.

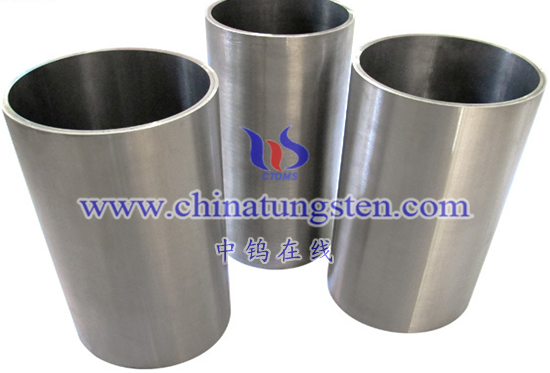

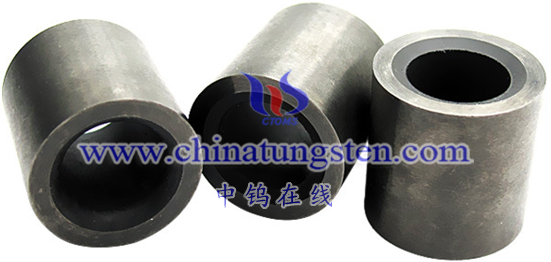

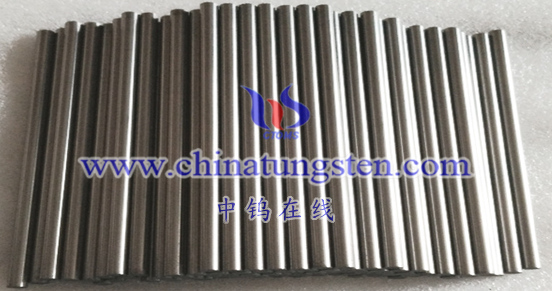

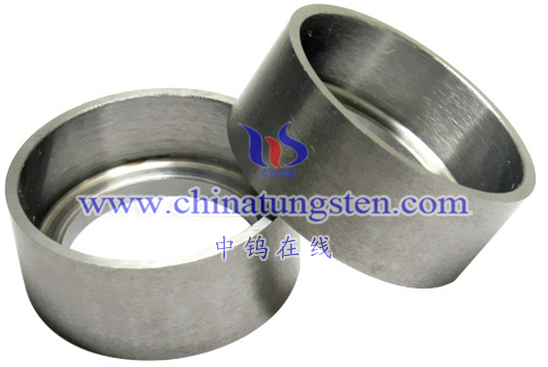

Common hot riveting bearing materials include some alloy materials, such as tungsten-molybdenum-nickel-iron alloy. This alloy exhibits excellent performance in bearing hot riveting processes due to its high hardness, high melting point, good thermal conductivity and chemical stability. In addition, other types of alloys, such as copper-based alloys, iron-based alloys, etc., may also be used as hot riveting bearing materials according to specific application scenarios and needs.

When selecting hot riveting bearing materials, you also need to consider the working environment and usage conditions of the bearing. For example, bearings operating in high-temperature environments need to have excellent heat resistance and oxidation resistance; in heavy loads or high-speed operation, bearing materials need to have sufficient strength and wear resistance.

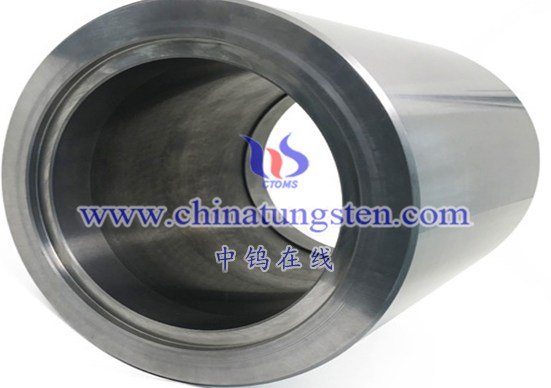

At the same time, the hot riveting process itself also needs to consider the thermal expansion coefficient and thermal conductivity of the material. A suitable thermal expansion coefficient can ensure a tight fit between materials during the hot riveting process, while good thermal conductivity helps distribute heat quickly and evenly to avoid problems such as local overheating or uneven cooling.

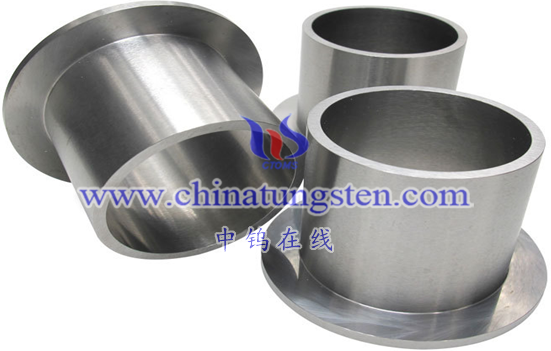

The application of tungsten-molybdenum-nickel-iron alloy in hot riveting bearing materials is mainly reflected in its advantages as a high-temperature bearing material. Due to its good overall high temperature properties, this alloy is particularly suitable for bearing applications that need to withstand high temperatures and heavy loads.

Specifically, the high hardness, strength and good wear resistance of tungsten-molybdenum-nickel-iron alloy make it an ideal choice for hot riveting bearings. In high-temperature environments, the alloy can maintain good dimensional stability and mechanical properties, thereby ensuring normal operation and extending service life of the bearings.

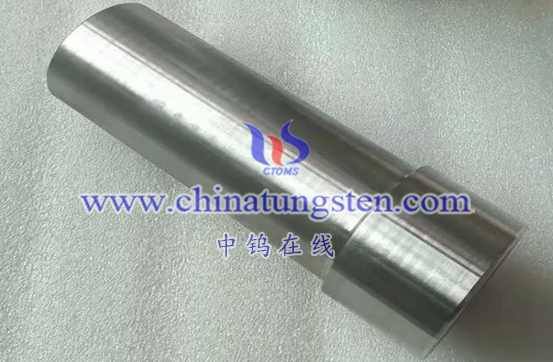

In addition, tungsten-molybdenum-nickel-iron alloy also has good thermal conductivity, which means that it can effectively transfer and dissipate heat and reduce the thermal stress generated by the bearing during operation. This feature is critical to preventing thermal failure of the bearing and improving overall performance.

It should be noted that although tungsten-molybdenum-nickel-iron alloy is widely used in hot riveting bearing materials, in specific applications it is necessary to select the appropriate alloy composition and manufacturing process according to the working conditions and requirements to ensure the best performance of the bearing. and reliability.

In summary, tungsten-molybdenum-nickel-iron alloy, as a hot riveting bearing material, relies on its excellent high-temperature performance, hardness and wear resistance, as well as good thermal conductivity, to provide reliable and stable operation of bearings in high-temperature and heavy-load environments. Assure.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595