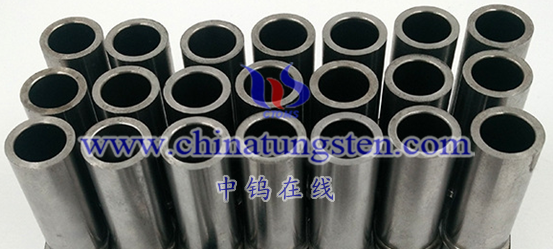

High-temperature bearings refer to bearings with operating temperatures higher than 120°C, and their parts require special high-temperature tempering and stable dimensional processing. The cage is usually made of brass or ferrosilicon alloy, and bearings above 160°C require high-temperature grease. The material, model and structure of this bearing have its own uniqueness.

The materials of high-temperature bearings are generally divided into three types: high-temperature tempered bearing steel, high-temperature alloy steel, and silicon nitride ceramics. Among them, full-bead high-temperature bearings made of bearing steel can withstand high temperatures of 150~200°C, full-bead bearings made of high-temperature alloy steel can withstand high temperatures of 300~500°C, and full-bead bearings made of silicon nitride can withstand high temperatures of 800~1200°C. ℃.

The models of high-temperature bearings are also different from ordinary bearings. The meanings of the suffix codes for high-temperature bearings made of bearing steel include: S0 means that the parts have been tempered by high temperature, and the working temperature can reach 150°C; S1 means that the parts have been tempered by high temperature, and the working temperature can reach 200°C; and so on, S4 means The parts are tempered at high temperature and the working temperature can reach 350℃.

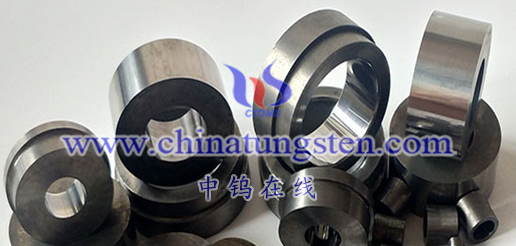

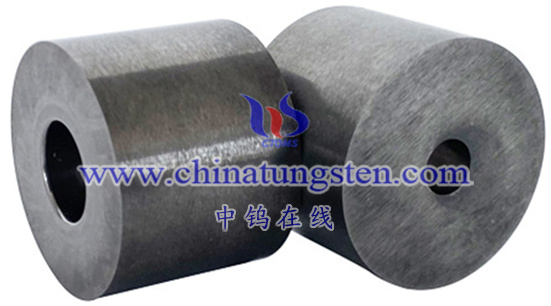

There are also many structural types of high-temperature bearings, such as full-bead high-temperature bearings and high-speed high-temperature bearings. The structure of full-bead high-temperature bearings is full of rolling elements, and the material can be bearing steel, high-temperature alloy steel or silicon nitride. High-speed and high-temperature bearings contain cages, have higher rotation speeds, and are generally made of high-temperature alloy steel. When selecting high-temperature bearings, you need to select based on the actual application scenario. For example, in harsh environments and high-speed situations, you must choose bearings with cages, seals, and imported high-temperature grease.

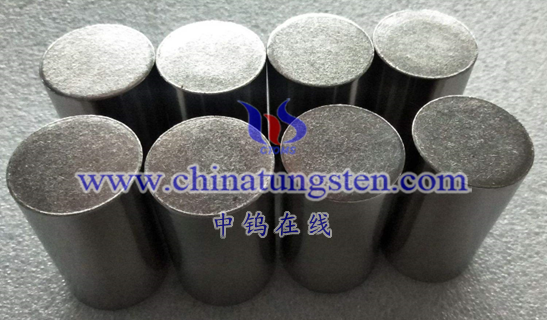

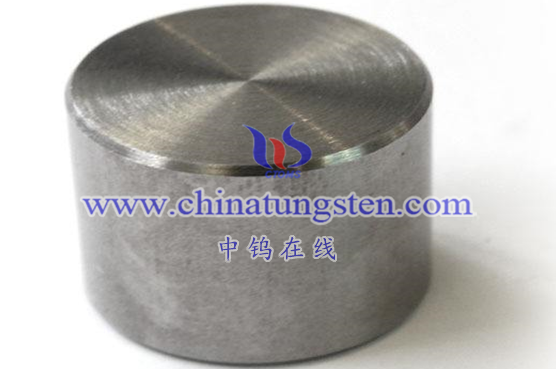

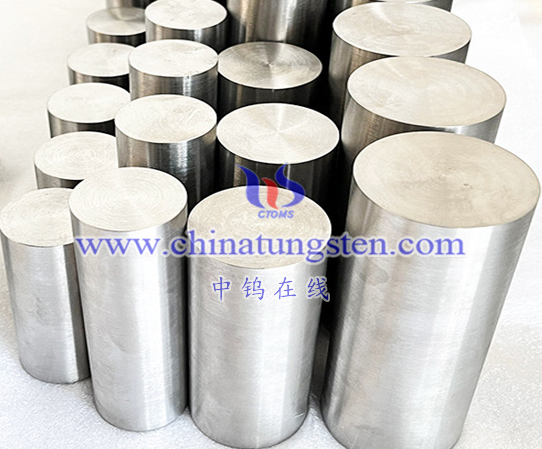

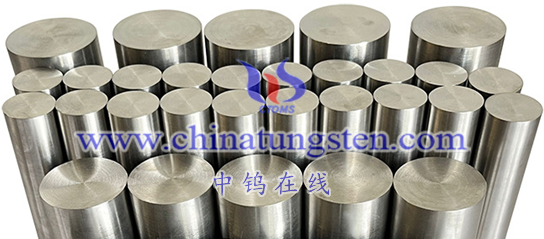

The application of tungsten-molybdenum-nickel-iron alloy in high-temperature bearing materials has significant advantages and some potential disadvantages. The following is an analysis of the advantages and disadvantages of its application:

Advantages of tungsten-molybdenum-nickel-iron alloy:

High thermal stability

The alloy can maintain good dimensional stability and mechanical properties in high temperature environments, which is crucial for bearings to work at high temperatures.

good wear resistance

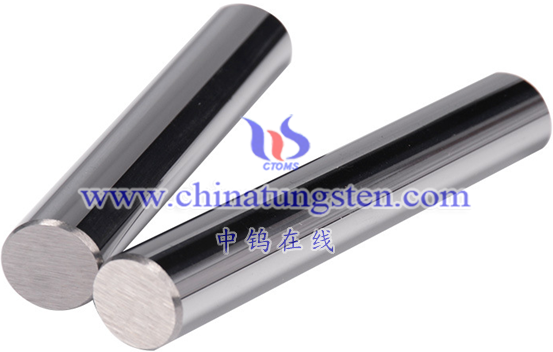

Tungsten-molybdenum-nickel-iron alloy has excellent wear resistance, which can effectively resist the wear of the bearing during work and extend the service life of the bearing.

high strength

The alloy has high strength and good load-bearing capacity and can withstand the high loads generated by the bearing during operation.

good thermal conductivity

Tungsten-molybdenum-nickel-iron alloy has high thermal conductivity, which can quickly transfer and dissipate heat, reduce the thermal stress generated by the bearing during operation, and prevent thermal failure.

Disadvantages of tungsten-molybdenum-nickel-iron alloy:

higher cost

Due to the rarity and high cost of elements such as tungsten and molybdenum, the production cost of tungsten-molybdenum-nickel-iron alloy is relatively high, which may make its price higher.

Processing difficulty

The alloy’s high hardness may make processing more difficult, requiring special processing techniques and equipment.

Requirements for lubrication

Although tungsten-molybdenum-nickel-iron alloy has good wear resistance, proper lubrication is still required to ensure the normal operation of the bearings under high temperature and heavy load conditions. Improper lubrication can lead to increased bearing wear.

Generally speaking, the application of tungsten-molybdenum-nickel-iron alloy in high-temperature bearing materials has significant advantages, especially in situations that need to withstand high temperatures, heavy loads and high-speed operations. However, its high cost and difficulty in processing, as well as its requirements for lubrication, also need to be considered in applications. In practical applications, its suitability needs to be evaluated based on specific working conditions and requirements.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595